Advances in autonomous robotics for industrial applications

Advances in autonomous robotics for industrial applications increase efficiency, improve safety, and enhance quality control, driving productivity while addressing challenges such as high costs and integration with existing systems.

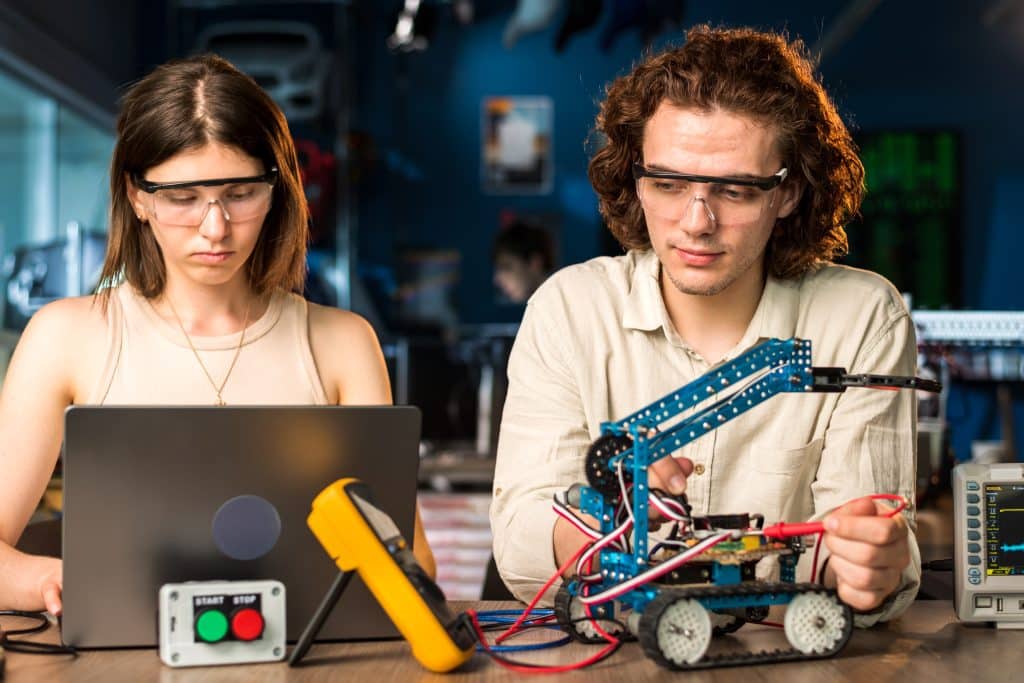

Advances in autonomous robotics for industrial applications are reshaping how industries approach productivity and safety. Imagine a factory where robots work alongside humans, enhancing efficiency and reducing risks. Curious about how these technologies are changing the game?

Understanding autonomous robotics

Understanding autonomous robotics is crucial in the modern industrial landscape. These advanced systems are designed to operate independently, performing tasks with minimal human intervention. They leverage sophisticated algorithms and sensors to navigate their environments efficiently.

What Makes Robotics Autonomous?

At the core of autonomy in robots are key technologies that allow them to perform their designated roles. Artificial intelligence plays a vital role, as it enables robots to learn from their environments and make decisions. Machine learning and computer vision are essential components that enhance these capabilities.

- Machine Learning: Helps robots improve their performance over time through data analysis.

- Computer Vision: Allows robots to perceive and understand their surroundings.

- Sensor Technology: Facilitates accurate navigation and task execution.

Autonomous robots are not limited to traditional manufacturing roles. They are increasingly found in logistics, agriculture, and even healthcare. These robots can sort packages, assist in surgeries, and monitor crops, showcasing their versatility and adaptability.

Benefits of Autonomous Robotics

By integrating autonomous robots into industrial applications, companies experience numerous advantages. First, productivity can significantly increase, as robots can work tirelessly without breaks. Furthermore, quality control improves as robots execute tasks with high precision.

Moreover, operational safety is enhanced. Robots can undertake dangerous jobs, reducing the risk of workplace accidents. As industries embrace these changes, it’s important to adapt and understand how to best implement these technologies.

In conclusion, understanding the principles behind autonomous robotics helps businesses leverage these technologies for optimal results. These systems are paving the way for a more efficient and safe industrial future.

Key innovations in robotics technology

Key innovations in robotics technology have transformed how industries operate. These advancements enable robots to perform tasks more accurately and efficiently. Understanding these innovations is essential for optimizing industrial applications.

1. Advanced Sensors

Advanced sensors play a critical role in modern robotics. They allow machines to gather data about their environment. This capability enhances navigation and operational safety. Sensors can detect obstacles, measure distances, and identify objects.

- Lidar: Provides precise distance measurement using laser light.

- Infrared Sensors: Enhance detection capabilities in low-light environments.

- Vision Systems: Use cameras to interpret visual information and aid in decision-making.

These sensors are crucial for autonomous robots working in unpredictable environments. They help robots adapt to changes in real time, making processes smoother and safer.

2. Artificial Intelligence

Artificial intelligence (AI) is a game-changer in robotics. AI algorithms allow robots to learn from experience and improve over time. This means they can handle complex tasks without constant human guidance. For instance, AI enables robots to analyze data, recognize patterns, and make informed decisions based on their surroundings.

In industries like manufacturing and logistics, implementing AI enhances productivity and reduces human error. Robots can optimize workflows, adapt to new challenges, and increase efficiency significantly.

3. Collaborative Robots

Collaborative robots, or cobots, are designed to work alongside humans. They are equipped with advanced safety features that allow them to operate in close proximity to workers. This innovation has revolutionized production lines, allowing for a blend of manual and automated processes.

Cobots can assist with repetitive tasks, freeing workers to focus on more complex activities. The integration of cobots boosts productivity while ensuring a safer work environment.

The ongoing research and development in robotics technology continue to push boundaries. As innovations emerge, they will lead to even smarter, more efficient systems, driving the future of industry forward.

Benefits of autonomous systems in industries

The benefits of autonomous systems in industries are numerous and impactful. These systems revolutionize operations by enhancing efficiency and safety across various sectors. By integrating autonomous technologies, companies experience substantial improvements in productivity.

1. Increased Efficiency

One significant advantage is the ability of autonomous systems to operate continuously without breaks. This leads to higher output and faster completion of tasks. For example, robots can work around the clock, handling repetitive tasks that would tire human workers. Consequently, organizations can achieve more in less time.

- Continuous operation: Reduces downtime and maximizes productivity.

- Fast processing: Accelerates workflows and decreases lead times.

- Optimized resource use: Lowers waste and enhances material handling.

This efficiency not only saves time but also reduces operational costs, allowing companies to allocate resources more effectively.

2. Improved Safety

Autonomous systems also play a vital role in improving workplace safety. These technologies can perform hazardous tasks, minimizing the risk to human workers. In industries such as construction and manufacturing, robots can handle heavy lifting or operate in dangerous environments.

By taking on these demanding roles, autonomous systems help prevent accidents and injuries. They enable a safer work environment, which can boost employee morale and reduce liability costs.

3. Enhanced Quality Control

Another key benefit is the improvement in quality control. Autonomous systems can monitor processes in real-time, ensuring that products meet strict quality standards. They can detect defects and make adjustments instantly, leading to fewer errors.

Automated inspections allow for consistent quality, decreasing the variation in production outcomes. This reliability strengthens customer trust and can enhance brand reputation.

Overall, the deployment of autonomous systems in industries fosters significant advantages, transforming how businesses operate and position themselves in competitive markets. As these technologies continue to advance, their impact on efficiency, safety, and quality will only grow.

Challenges faced in robotics implementation

Implementing robotics in industries brings many benefits, but it also presents several challenges. Understanding these challenges is crucial for successful integration. Companies must be prepared to address potential obstacles to maximize the advantages of automation.

1. High Initial Costs

One major challenge is the high initial cost of adopting robotics technology. Purchasing and installing robotic systems can be expensive, making it difficult for smaller companies to invest. Additional costs include training employees to operate and maintain these systems.

- Cost of equipment: Robots and automation technologies often require significant upfront investment.

- Maintenance costs: Keeping robots in optimal condition can add to long-term expenses.

- Training expenses: Employees need training to work effectively with new systems.

Despite these costs, companies often find that the long-term savings and increased productivity make the investment worthwhile.

2. Integration with Existing Systems

Another challenge is integrating new robotic systems with existing processes and technologies. Companies often have legacy systems that may not easily work with new automation tools. This integration requires careful planning and sometimes custom solutions.

The transition can disrupt operations if not managed properly. Companies must consider how to align new robotics with their current workflows to minimize downtime and maintain productivity.

3. Skills Gap

The rapid advancement of robotics technology leads to a skills gap in the workforce. Many employees may lack the technical skills necessary to operate and manage modern robotic systems. Bridging this gap requires substantial investment in training and development.

Employers may also face difficulties in finding qualified candidates who are well-versed in robotics and automation. As such, upskilling current employees is essential for maximizing the benefits of robotics implementation.

Overall, while the challenges of adopting robotics can be significant, companies that navigate these obstacles strategically can position themselves for success in an increasingly automated world.

Future trends in autonomous robotics

The future trends in autonomous robotics are exciting and transformative. As technology advances, we can expect significant changes that will shape industries positively. These trends focus on improving efficiency, safety, and the integration of new technologies.

1. Enhanced Artificial Intelligence

One major trend is the development of more sophisticated artificial intelligence systems that enable robots to learn and adapt better. This means robots will increasingly be able to perform complex tasks with greater accuracy. Machine learning algorithms will allow them to process data in real-time and improve their functions.

- Self-learning capabilities: Robots will learn from their experiences and optimize their operations.

- Predictive analytics: AI will help robots anticipate issues and find solutions before problems occur.

- Natural language processing: Robots will understand human commands better, improving collaboration.

This enhancement in AI will empower robots to handle more complicated roles across various industries.

2. Integration of IoT

The Internet of Things (IoT) is another significant trend shaping the future of robotics. By connecting robots to the IoT, they can communicate with other devices, share data, and operate more cohesively. This integration will lead to smarter systems that can optimize workflows automatically.

For example, robots on a manufacturing floor can share real-time data with supply chain systems. This communication helps streamline processes and improve overall productivity.

3. Collaborative Robots (Cobots)

Another important trend is the rise of collaborative robots, or cobots. These robots are designed to work alongside human workers rather than replace them. Cobots will become more prevalent in workplaces, assisting with various tasks while ensuring safety and efficiency.

With improved sensors and AI, cobots will be able to interact safely with humans. They can take on repetitive or physically demanding tasks, allowing human workers to focus on more complex and creative responsibilities.

In summary, the future of autonomous robotics promises to be revolutionary, driven by enhanced AI, IoT integration, and collaborative robots. These innovations will redefine industries and create new opportunities for businesses and workers alike.

FAQ – Frequently Asked Questions about Advances in Autonomous Robotics

What are the main benefits of adopting autonomous robotics in industries?

The main benefits include increased efficiency, improved safety, and enhanced quality control, leading to higher productivity and reduced costs.

How does artificial intelligence enhance the capabilities of autonomous robots?

Artificial intelligence allows robots to learn from their experiences, adapt to new situations, and perform tasks autonomously with greater accuracy.

What challenges do companies face when implementing robotics?

Companies often face high initial costs, integration with existing systems, and a skills gap in the workforce required to operate the new technology.

What trends should we expect in the future of autonomous robotics?

Future trends include enhanced AI capabilities, better integration with the Internet of Things (IoT), and an increase in collaborative robots that work alongside human workers.